In today’s fast-paced logistics and warehousing environments, the reliance on electric forklifts has become increasingly prominent. At the heart of these essential vehicles lies the battery, a component that demands meticulous care for optimal performance and longevity. This comprehensive guide delves into the nuances of forklift battery maintenance and optimization, particularly for electric models, providing insights into best practices for charging, storage, handling, and extending battery life while enhancing overall energy efficiency.

Understanding Forklift Battery Dynamics

Forklifts predominantly use lead-acid and lithium-ion batteries. The former, known for its cost-effectiveness, has been a traditional choice, while the latter is celebrated for its longer lifespan and swifter charging capabilities. Recognizing the type of battery in your forklift is the first step towards tailored maintenance.

Charging Practices for Peak Performance

Regular and timely charging forms the backbone of battery care. It’s recommended to charge the battery after each shift or when it dips to 20-30% capacity. However, overcharging can be detrimental, leading to a shortened lifespan. Ensuring the battery isn’t left on the charger beyond the required time is key.

Charging should occur in a well-ventilated area, ideally within the temperature range suggested by the manufacturer, usually between 50°F and 86°F. Keeping the charging area clean and free from debris prevents contamination and ensures safety.

Storage and Handling: Ensuring Longevity and Safety

When it comes to long-term storage, a partially charged state, around 40-50%, is ideal. The storage environment should be cool, dry, and shielded from extreme temperatures. Handling batteries safely is crucial; wearing protective gear and employing correct lifting techniques are non-negotiable practices to prevent accidents.

Routine Maintenance: The Lifeline of Forklift Batteries

Keeping the battery free from dust and dirt through regular cleaning, and inspecting for damage or leaks, ensures it remains in optimal condition. For lead-acid batteries, maintaining the correct water level is vital. The water should just cover the lead plates and be replenished with distilled or deionized water as needed.

Optimizing Battery Life and Energy Efficiency

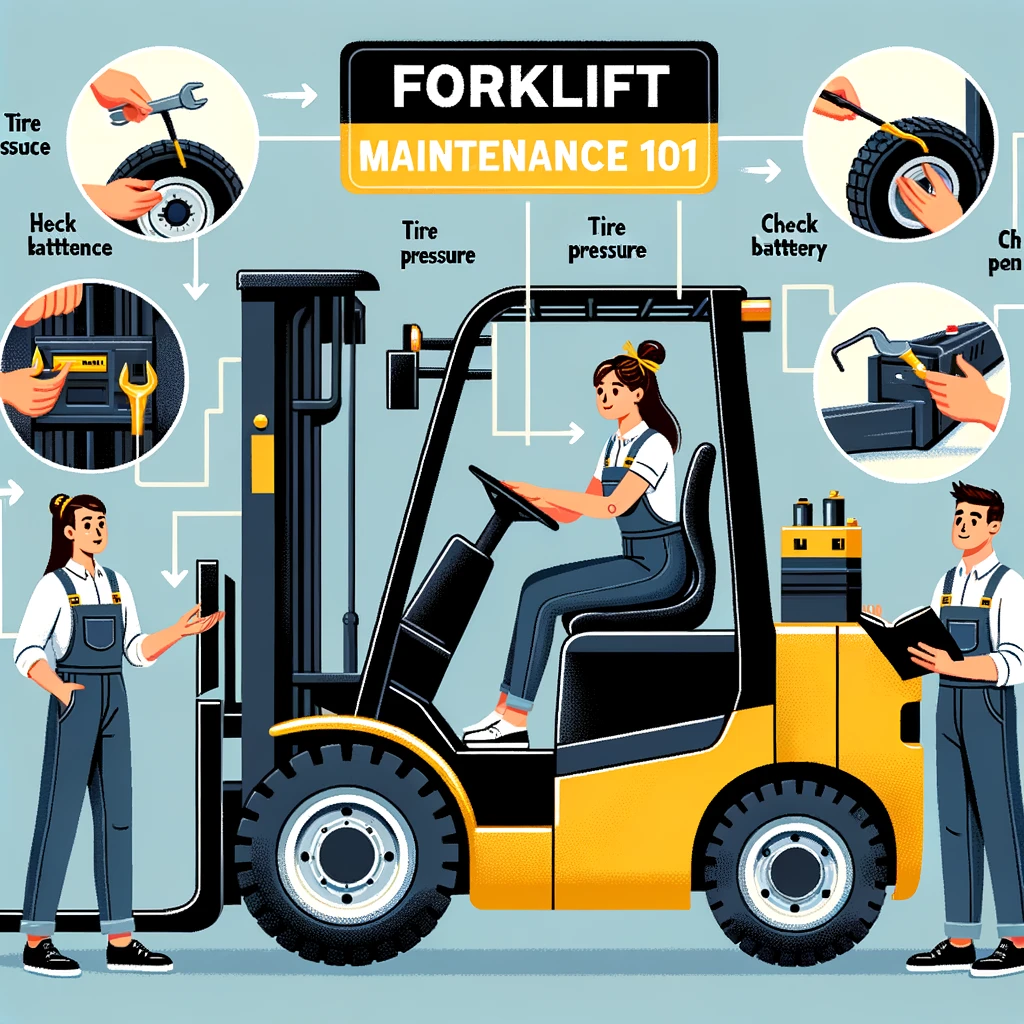

Rotating between multiple batteries and managing forklift loads efficiently can prevent premature wear and tear. Additionally, regular maintenance of the forklift itself, including the tires, brakes, and electrical systems, contributes significantly to battery efficiency.

Training operators in energy-efficient driving habits, like smooth acceleration and minimizing idle time, also plays a crucial role in maximizing battery performance.

Conclusion: The Heartbeat of Your Forklift

In essence, the health of your forklift battery is a direct reflection of the productivity and operational costs of your business. By embracing these best practices in battery care, charging routines, and energy-efficient operations, you can significantly enhance the performance and lifespan of your electric forklift batteries. Remember, efficient battery maintenance is not just about prolonging its life; it’s about ensuring the seamless and cost-effective functioning of your logistics and warehousing operations.